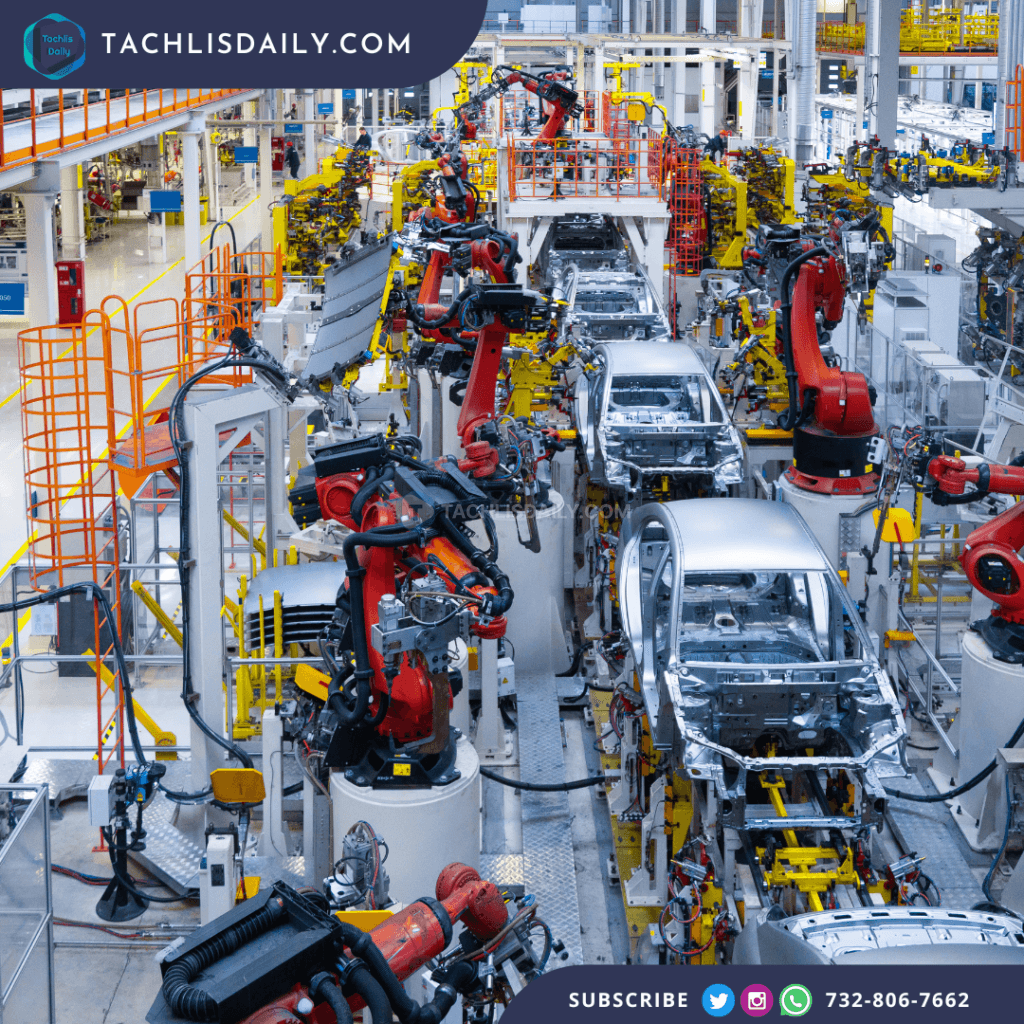

Honda is making a major push into electric vehicle production with a $1 billion investment in its Ohio facilities, marking a significant milestone in the company’s transition to EVs. The investment will bring six state-of-the-art “giga presses” and a new “cell” manufacturing system for battery cases, revolutionizing the automaker’s production process. This move positions Ohio as the central hub for Honda’s EV manufacturing strategy, a departure from the company’s traditional approach of first implementing major changes in Japan.

The company’s Marysville plant will be upgraded to produce gasoline, hybrid, and fully electric vehicles on a single assembly line, an innovation that enhances efficiency and flexibility. This expansion is part of Honda’s broader EV strategy, which includes a $3.5 billion battery plant in Ohio and the introduction of new electric models, such as the all-electric Acura RSX crossover.

By implementing cutting-edge “gigacasting” technology, Honda aims to reduce production costs and increase sustainability by using recyclable structural aluminum for battery packs. The company remains committed to its goal of achieving carbon neutrality by 2050 and selling only zero-emission vehicles by 2040, despite slowing EV adoption across the industry. Honda’s Ohio transformation represents a critical step in reimagining its manufacturing processes and solidifying its place in the EV market.